Intelligent SMD Storage System YST15 YAMAHA SMT

From: Author: Publish time:2021-09-06 13:52 Clicks:0

Intelligent SMD Storage System YST15 Feature

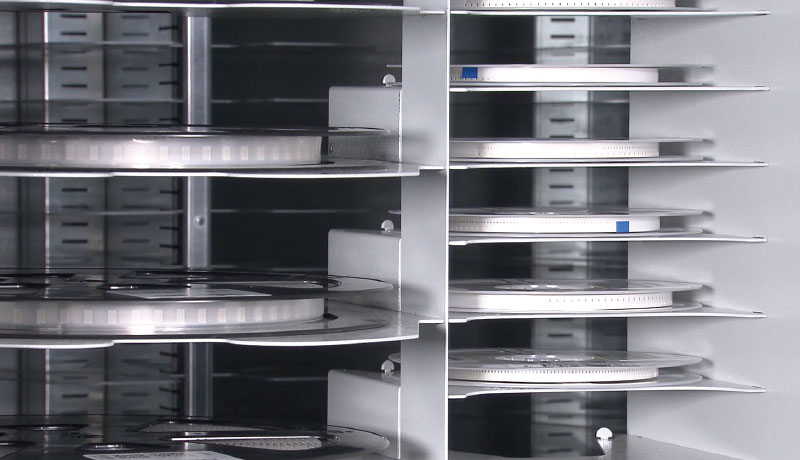

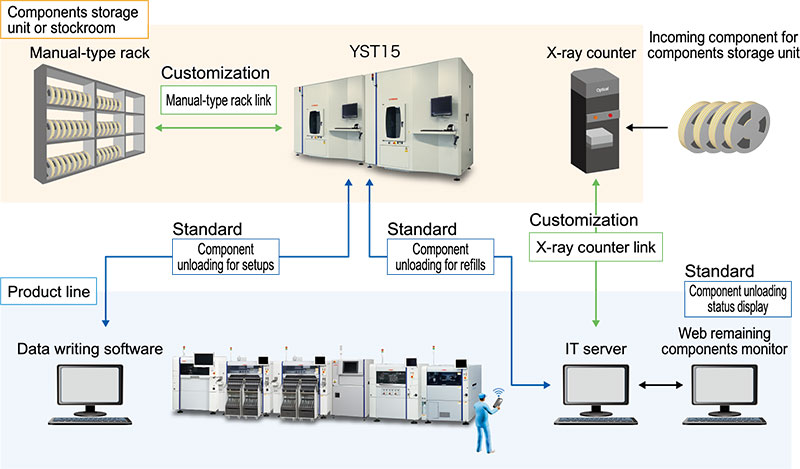

An intelligent automated storage system that does highly efficient component loading / unloading and refills by Direct Handling and Reel Components Batch loading / unloading

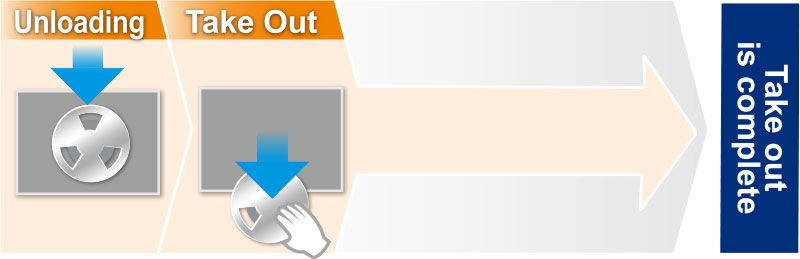

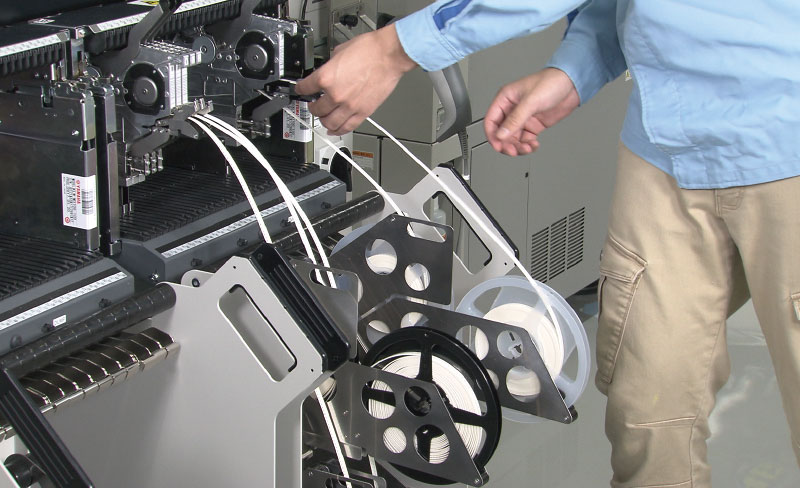

Directly unloads just each required reel. No dedicated storage box required and work efficiency greatly improved.

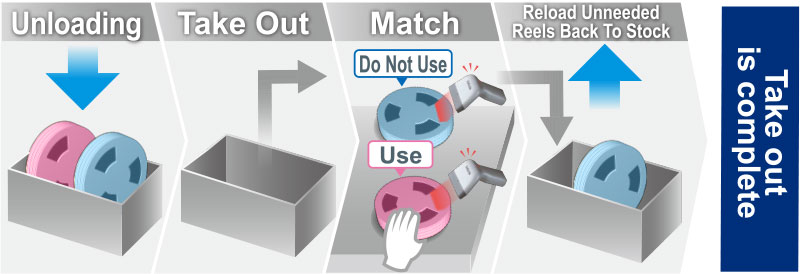

Direct Handling unloads just the reels you need. Compared to systems that unload several unneeded reels in a dedicated box there is no need to return unneeded reels so efficient component unloading is achieved.

Only unloads the reels that are needed and does not unload the reels that are not needed, so there is no need to verify them when you taking out the reels. This reduces the operator's workload.

Direct handling eliminates the dedicated storage boxes for reel components. (Except for some components) This realizes cost savings and there is no need to save the box storage space.

Multiple reels can be loaded or unloaded at the same time. This means that this time can be effectively used for other tasks while YST15 is loading or unloading components compared to the automated storage where loading just 1 reel at a time.

The reels are directly gripped during direct handling so that even different size reels can be unloaded. YST15 handles many different component types so the unloading operation is more streamlined and efficient.

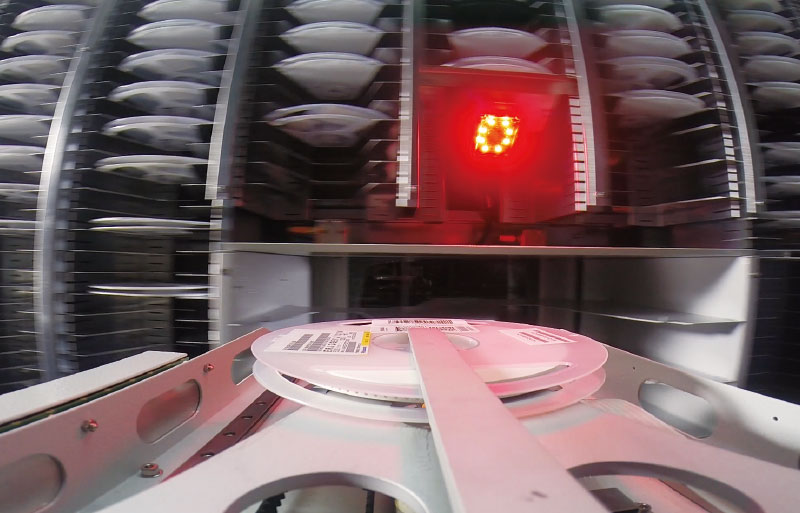

The component storage internal barcode reader automatically scans the barcodes on all reels during batch loading. This prevents read-out errors caused by human error and eliminates the scanning process, making the receiving process more efficient.

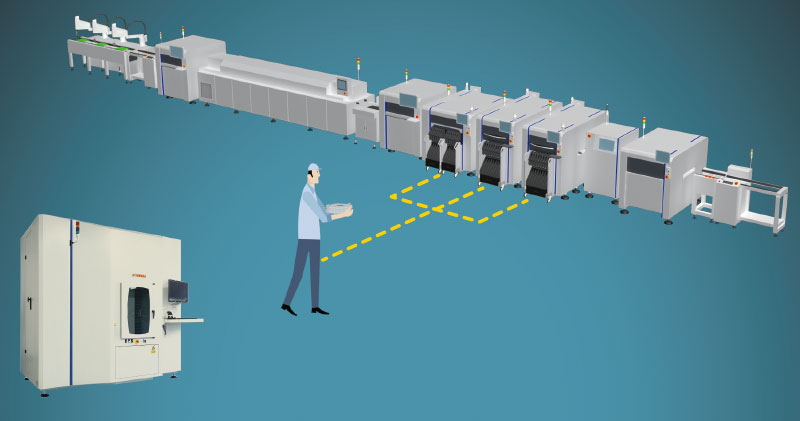

After receiving a mounter component remaining component warning, the next required components can be automatically unloaded from stock. The components are placed on the fast extraction shelf in priority over other components, allowing the operator to take them immediately. In addition, components that will be needed in a certain period of time can be unloaded in batches based on the information on the number of components remaining on the mounter. This operation is highly compatible with Auto Loading Feeder and greatly improves efficiency when refilling the mounter with components.

Components needed for the setup are automatically unloaded from the setup list created on the Yamaha Offline software. The number of feeders to place on the Yamaha feeder carriage (holds 32 feeders/8mm width) can all be unloaded in one batch. This helps made efficient setups by unloading components in specified carriage units. Lists can also be imported from other systems.

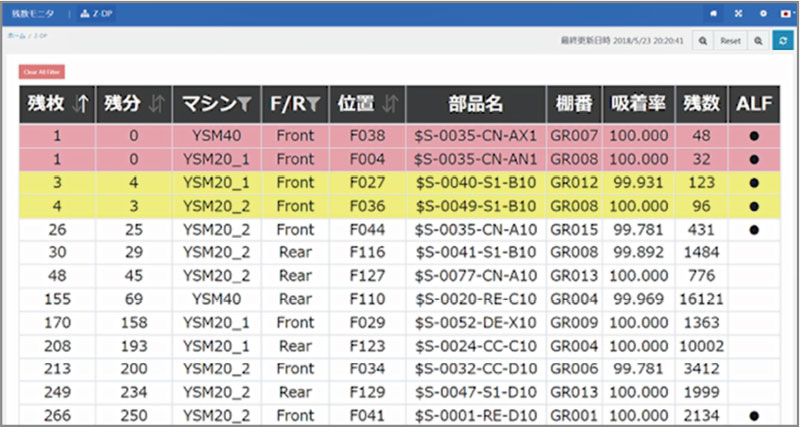

The status of components required during production, including the status of YST15 unloading and the status of reservations, are displayed on the monitor of the web browser. This information is displayed on a large-size monitor or tablets so the component pickup and collection tasks can be efficiently performed at the required timing.

A humidity control function is installed as a standard feature, which can also be used for components that require moisture-proof control. The dehumidifiers operate in turns 24 hours a day to dehumidify the inside of the storage unit.

The YST15 also manages the usage expiration dates of stored components. This feature limits unloading expired components to prevent defects from occurring due to mistakenly using those components.

This feature monitors the temperature within the component storage unit and confirms whether the components can be stored at the correct temperature. This supports quality maintenance.

These set the first-in, first-out priorities for materials including priority unloading by manufacturing date and priority unloading for currently used components.

LED Panel Ceiling Light Assembly Line, Desk Type Reflow Oven, Double Platform Wave Soldering Machine For Iphone, SMD Mounting Machine, Siemens SMT Machine, PCB Mounting Machine, SMT Equipment For Sale, PICk And Place Packaging Machine, Fuji Nxt 3 SMT Machine, Fuji PICk And Place Machine, UltrasonIC Cleaner MICro PCB, PCB Board Rosin Cleaner Machine, PneumatIC Equipment Stencil Cleaner, AutomatIC UltrasonIC Stencil Cleaning Machine, Screw Robot IndICated Machine, Robot Tool Screw Vacuum, Screw Fasten Machin Robot, Screwdriver AutomatIC Screw Locking Robot

Direct handling for highly efficient Loading & Unloading

Direct handling brings a whole new level of efficiency to tasks

YST15 [Direct handling]

Box type

Only the reels you need are unloaded.

No need for component verification when taking out.

Eliminates the cost of preparing storage boxes and space to store them.

Batch Loading / Handling of up to 33 reels

Effectively use of waiting time during loading and unloading

Simultaneously unloads different size reels

Eguipped with built-in barcode reader as a standard

Mounter Collaboration functions support component setup & refill.

Component unloading for refills

Component unloading for Setups

Component unloading status display

Effective management of environment for correctly storing different components

Humidity Management

Time Limit Management

Temperature Monitoring

Unloading Priority Settings