YAMAHA Premium Modular Σ-G5SⅡ Feature

From: Author: Publish time:2021-09-02 16:07 Clicks:0

Premium Modular Σ-G5SⅡ Feature

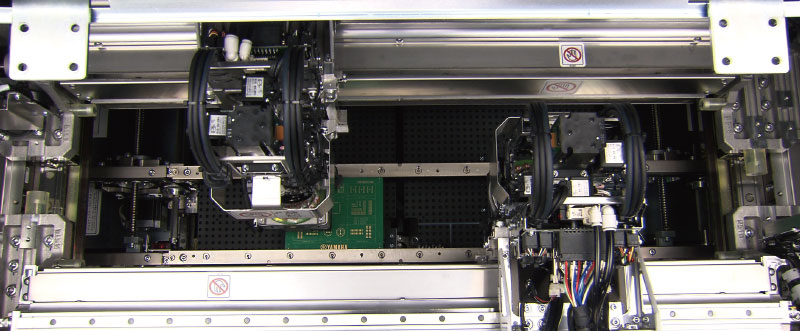

The “1-head solution” rotary head provides speed, versatility and high operating ratio.

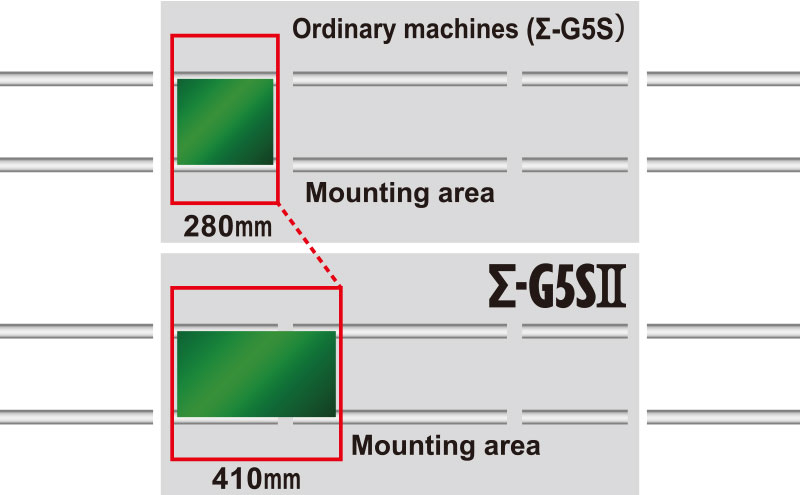

Using PCB standby for part of mounting area, allowed increasing buffer from conventional size of L280 millimeters to L410 millimeters.

LED Bulb Assembly Line Semi AutomatIC Machine, LED-Line Assembly-Machine, PCB Solder Paste Printer Semi, Semi AutomatIC Solder Paste Printer, LED Reflow Oven, Thermal Profiler Reflow Oven, Wave Soldering Machine Desktop DIP, Conformal Coating Spray Machine SMT, SMT Roll Wiper Rewinding Machine, SMT Peripherals PCB LED Dispensing Machine, SMT PCBA Pour Machine à Laver, Feeder Rack For SMT Asm Machine, Screening Conveyor SMT, AutomatIC PCB Loader, PCB Screening Conveyor, Screening Conveyor PCB, Conveyor Driver Board, PCB Circuit Boards Separator, Heating PCB Separator For Mobile Ipad

Achieves streamlined, high efficiency production

Overdrive motion

Reduced PCB transfer loss by enlarging buffer size

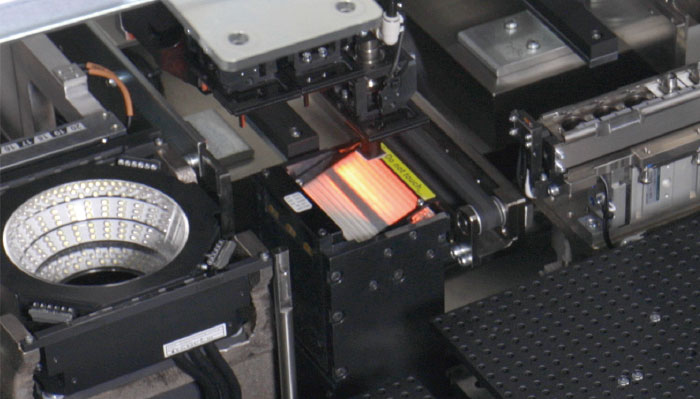

Achieves high-speed, high accuracy and high quality mounting

High-speed one-by-one pickup & mounting

Side-view function

Even on rotary heads, Yamaha gives the 1-head solution!

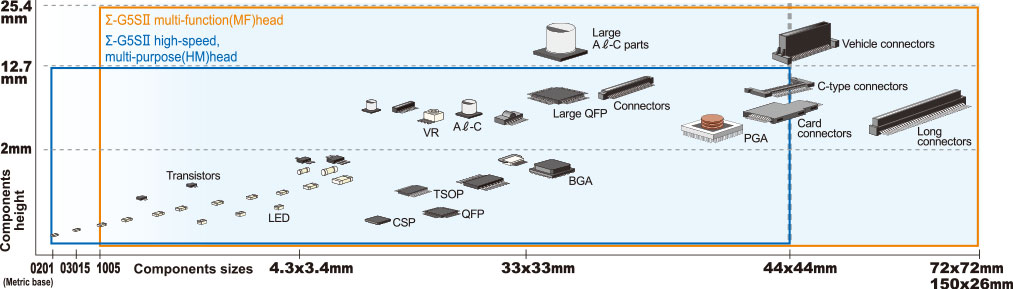

Head variations & compatible components

Includes coplanarity for high-speed and high-reliability

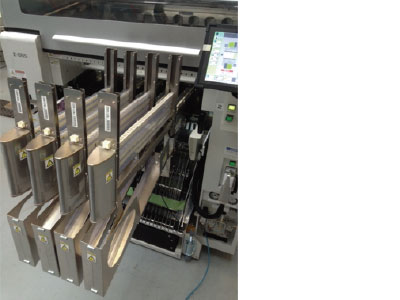

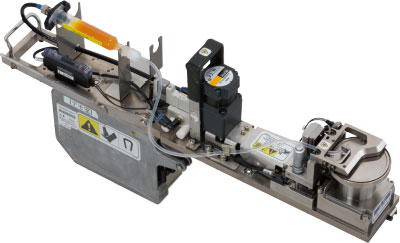

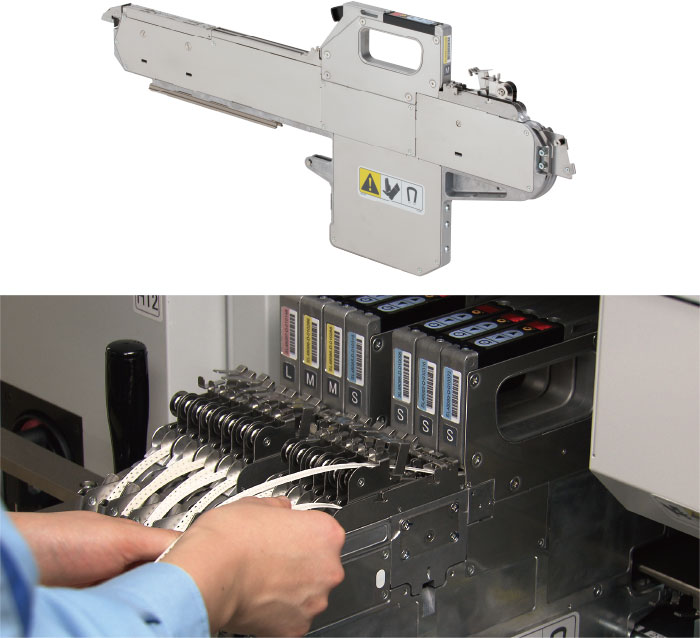

The Super Loading Feeder totally innovates components supply tasks!

Full range of feeder and supply device options to match your production format